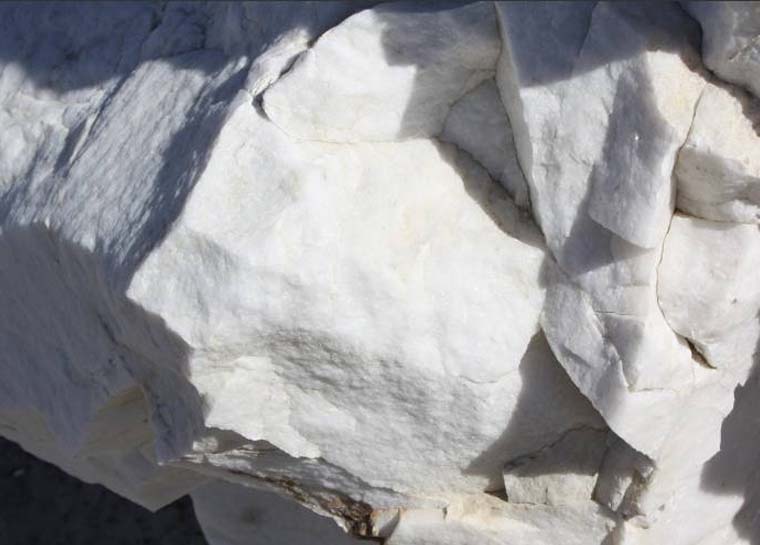

Calcium carbonate is known as gypsum, limestone, calcite, aragonite and marble. The chemical formula of calcium carbonate CaCO3, its appearance is pure powder white and its cream is whitish cream. The density of calcium carbonate decomposes from 2.71 to 2.83 g / cm2 at 825 ° C. It has a linear molecular shape and is non-flammable.

Applications of Calcium Carbonate

Paint Industry: In this industry, micronized powder is used as a filler. The specifications of the powder used in this industry are as follows:

Cao content more than 97% and Fe2O3 content less than 1% and its grading more than 500 mesh. Approximately 22% of the consumption of micronized powder in the Iranian paint industry is considered.

Cable and Wire Industry: Micronized powder is used for strength and as a filler in the amount of 20% for cable production and 10% for wire production. The specifications of the powder used should have a purity of 98%, a moisture content of less than 1% and a grain size of about 350 mesh.

Plastics and Rubber Industry: Micronized powder is used in this industry as a filler and product resistance to heat and strength. The specifications of micronized powder in this industry are such that the amount of CaO is at least 98%, the amount of moisture is at most 1%, the amount of Fe2O3 is at most 2%, and the pH is 8.5 to 9.5%.

Food and Pharmaceutical Industry: In these industries, micronized powder is used as a filler and production of antibiotics, antacids, dentistry and is used with 100% purity for the production of cosmetics and as a filler.

Paper Industry: The precipitated calcium carbonate is used as a turbidizer, smoother, filler and also to prevent the ink from spreading on the paper.

Detergent Industry: In this industry, micronized powder is used to prepare bleaching materials with special and soft size.

Oil Drilling industry: In drilling oil wells and in drilling fluid compositions, micronized powder with 85% purity and 325 mesh is used.

Plastic Shoes and Shoe Soles Industry (Suede and Synthetic Leather): In this industry, it is used as a filler of micronized powder with a grain size of a few microns and the outer surface is covered with a type of lubricant, which gives the following properties to the product:

- Exterior surface polish.

- Increases resistance to further tearing and stretching.

- It does not cause jaundice in the body and keeps the white color constant.

- Reduces elasticity.

- Fixed against fat.

Health industry: In this industry, micronized powder with 100% purity is used to produce toothpaste. Other applications of micronized powder include the production of machine-made carpets, macaroons, carpets, various types of carpet adhesives and other industries.

The Environment: To control air pollution, lime is used in metal smelters as well as absorbers of toxic gases such as HCl, HF, SO2.

Calcium Carbonate Plaster: One of these dry mortars is calcium carbonate plaster, which is used for indoor plastering. Some of its main properties are as follows:

- Prevent corrosion of steel parts in the building due to the presence of antioxidants.

- High initial setting time and the ability to operate the tool within 45 minutes.

- Hardness much higher than gypsum and comparable to concrete.

- High adhesion and can be applied on surfaces such as concrete, wood, pottery and 3D Panel.

- Low specific weight that makes the building light (1060 kg / m3).

- Fire and direct flame resistance.

- Resistance to heat and cold transfer, which makes the environment cool in hot seasons and warm in cold seasons.

- Moisture resistance.

- Very fast execution on the surfaces so that at least 80 to 120 square meters can be covered in each shift with a shotcrete machine.

- Fine grain size of 400 mesh and surface smoothness after application.

- Ability to mix with color pigments.

- Elimination of gypsum and soil in the building.

- Low price and competitive with ordinary plastering.

- Low secondary grip and competitive with conventional plastering.

- No surface cracks.

- It is free from any environmental pollution.

- Absence of adverse effects on the skin of the body at the time of application.

- High resistance to surface scratches.

Polyvinyl Chloride (PVC) Industry: Micronized powder is used to reinforce rubber objects and also to increase the strength and durability of this type of products, as well as to increase the formability and impact resistance against pressure and impact for hard PVC. It is estimated at approximately 25%. The specifications of micronized powder in this industry are as follows: Cao content more than 97%, Fe2o3 content less than 3% and grading more than 350 mesh.

Other applications include micronized powder, printing ink, glass-making, chimney desulfurization, in the welding and electrode industries, firefighting (preparation of fire extinguishing powders), agriculture, leather making, water treatment industry, sugar factories and Sugar, metallurgy, steel industry, pharmaceuticals, chemical industries as refractories, in food industries as acidity neutralizers and in making chewing gum, for cloud production, in textile and clothing industries, sculpture, false ceilings, and MDF, machine-made carpet production , Macalum, carpet, various types of carpet adhesives and other industries.

In general, the share of each of the consumed calcium carbonate includes: iron and steel 41%, construction industry 32%, environment 3%, chemical industry 6%, in paper making, sugar refining, leather making, agriculture and oil industry 8% And other applications is 10%.