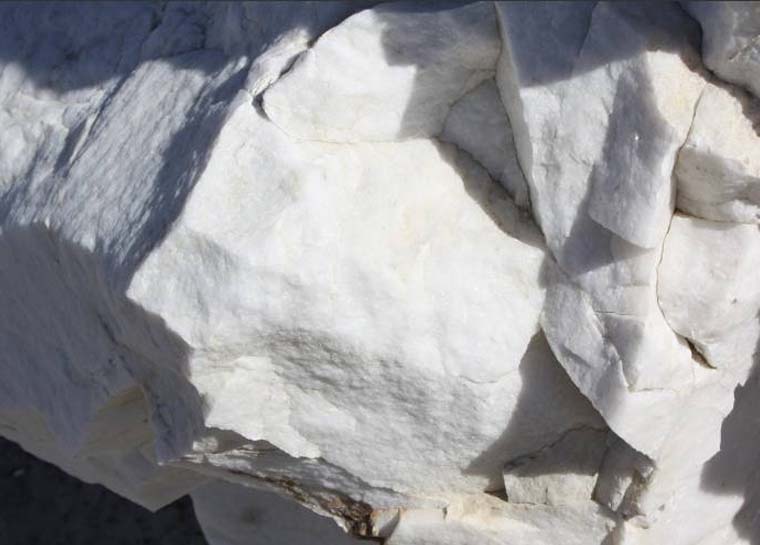

Due to its low melting temperature (115 ° C) and strong adhesion, sodium feldspar is used in the preparation of all kinds of clothes and glass, while potassium feldspar is mostly used as a melting aid and the main material for making ceramic structures. Since the consumption of potassium feldspar is at a higher level, its economic value is higher than that of sodium feldspar.

About 65% of alkaline feldspars are used in the glass industry, 30% in the ceramic industry, and another 5% as fillers in the paint, rubber, and other industries. In the glass industry, feldspar is used to supply the silica, aluminum and sodium required by glass, and alkane feldspar is used in the manufacture of various ceramic products. Potassium and sodium feldspars, which together form alkaline feldspars, are among the most widely used materials in the ceramic industry, and there are now many mines in Iran of both, especially the sodium type. In industry, feldspar mines are also referred to as industrial soils. Potash feldspar mines are smaller in number than other types and their soil is sold at a higher price.